Knowledge Base Chatbot for Manufacturing Teams: Floor Access

Manufacturing teams searching through binders and manuals for SOPs and specs? Wonderchat provides instant access to production procedures, equipment manuals, safety protocols, and quality specs via conversational AI—reducing downtime and improving floor efficiency.

Trusted by businesses worldwide

Why Manufacturing Operations Need AI Knowledge Base Access

Manufacturing floors are knowledge-intensive environments: production SOPs, equipment operation manuals, maintenance procedures, safety protocols, quality specifications, troubleshooting guides, and process documentation. Operators, technicians, and line supervisors need information constantly—but it's trapped in binders, filing cabinets, shared drives, or paper manuals scattered across the facility. Searching for the right procedure wastes production time, leads to errors, causes safety incidents, and creates quality issues. New operators take weeks to learn where information lives. Wonderchat deploys a knowledge base chatbot for manufacturing teams, making operational knowledge instantly accessible via mobile devices, floor kiosks, or tablets. Operators ask natural questions like "What's the torque spec for assembly step 5?" or "How do I clear error code E23 on Line 3 press?" and receive instant, accurate answers with citations to SOPs, manuals, or specs. Deploy in 5 minutes by uploading production SOPs, equipment manuals, safety procedures, quality specs, maintenance guides, and troubleshooting documents. Support floor workers with 100+ languages for diverse manufacturing workforces.

Emily

AI Agent

Wonderbot

Welcome to Wonderchat! How can I help you today?

hey i’d like to upgrade to enterprise please

Wonderbot

Sure, please hold on for a second.

Retrieving account details...

Retrieving account details...

Please confirm that you would like to upgrade to Wonderchat Enterprise. Your Visa card ending in 1234 will be charged $480.00 a year.

Cancel

Upgrade

Message...

Easy 5 minute set-up

How Wonderchat Works

Floor Knowledge Access

Provide Instant Procedure & Spec Lookup

Give manufacturing teams instant access to production SOPs, equipment operating procedures, maintenance instructions, safety protocols, quality specifications, and troubleshooting guides via conversational search—no binder or manual searching required.

SOP access

Equipment manuals

Quality specs

Floor Knowledge Access

Provide Instant Procedure & Spec Lookup

Give manufacturing teams instant access to production SOPs, equipment operating procedures, maintenance instructions, safety protocols, quality specifications, and troubleshooting guides via conversational search—no binder or manual searching required.

SOP access

Equipment manuals

Quality specs

Floor Knowledge Access

Provide Instant Procedure & Spec Lookup

Give manufacturing teams instant access to production SOPs, equipment operating procedures, maintenance instructions, safety protocols, quality specifications, and troubleshooting guides via conversational search—no binder or manual searching required.

SOP access

Equipment manuals

Quality specs

Manufacturing Documentation

Train on All Floor Documentation

Upload production SOPs, equipment operation manuals, maintenance procedures, safety protocols, quality specifications, troubleshooting guides, and process documentation to create an AI floor assistant with comprehensive operational knowledge.

Production SOPs

Equipment manuals

Safety protocols

Manufacturing Documentation

Train on All Floor Documentation

Upload production SOPs, equipment operation manuals, maintenance procedures, safety protocols, quality specifications, troubleshooting guides, and process documentation to create an AI floor assistant with comprehensive operational knowledge.

Production SOPs

Equipment manuals

Safety protocols

Manufacturing Documentation

Train on All Floor Documentation

Upload production SOPs, equipment operation manuals, maintenance procedures, safety protocols, quality specifications, troubleshooting guides, and process documentation to create an AI floor assistant with comprehensive operational knowledge.

Production SOPs

Equipment manuals

Safety protocols

Production Support

Reduce Downtime with Instant Answers

Help operators quickly resolve equipment errors, find correct torque specs, access maintenance procedures, and troubleshoot production issues without leaving the floor or waiting for engineering support—minimizing downtime.

Error resolution

Spec lookup

Troubleshooting guidance

Production Support

Reduce Downtime with Instant Answers

Help operators quickly resolve equipment errors, find correct torque specs, access maintenance procedures, and troubleshoot production issues without leaving the floor or waiting for engineering support—minimizing downtime.

Error resolution

Spec lookup

Troubleshooting guidance

Production Support

Reduce Downtime with Instant Answers

Help operators quickly resolve equipment errors, find correct torque specs, access maintenance procedures, and troubleshoot production issues without leaving the floor or waiting for engineering support—minimizing downtime.

Error resolution

Spec lookup

Troubleshooting guidance

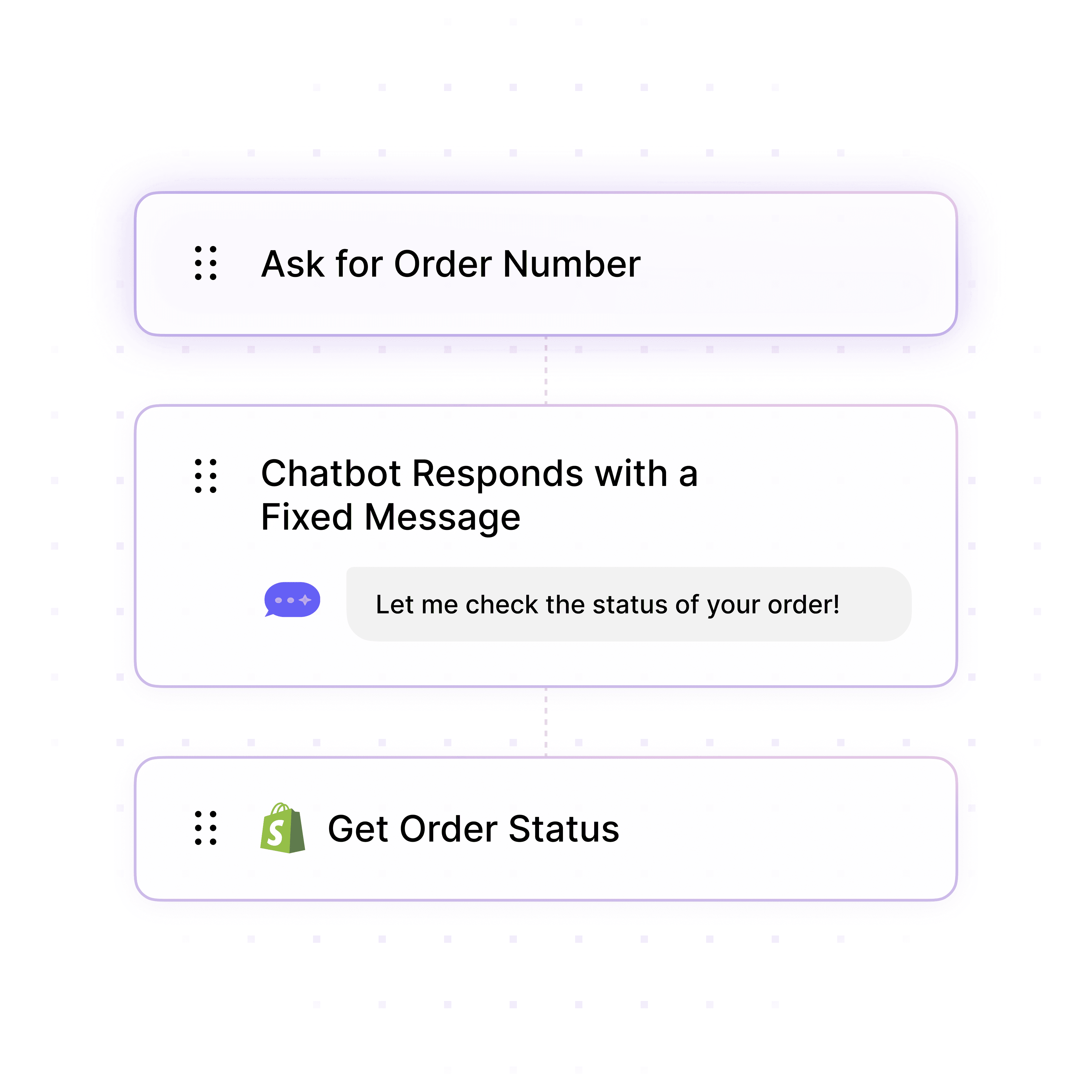

5-minute set up with our native integration

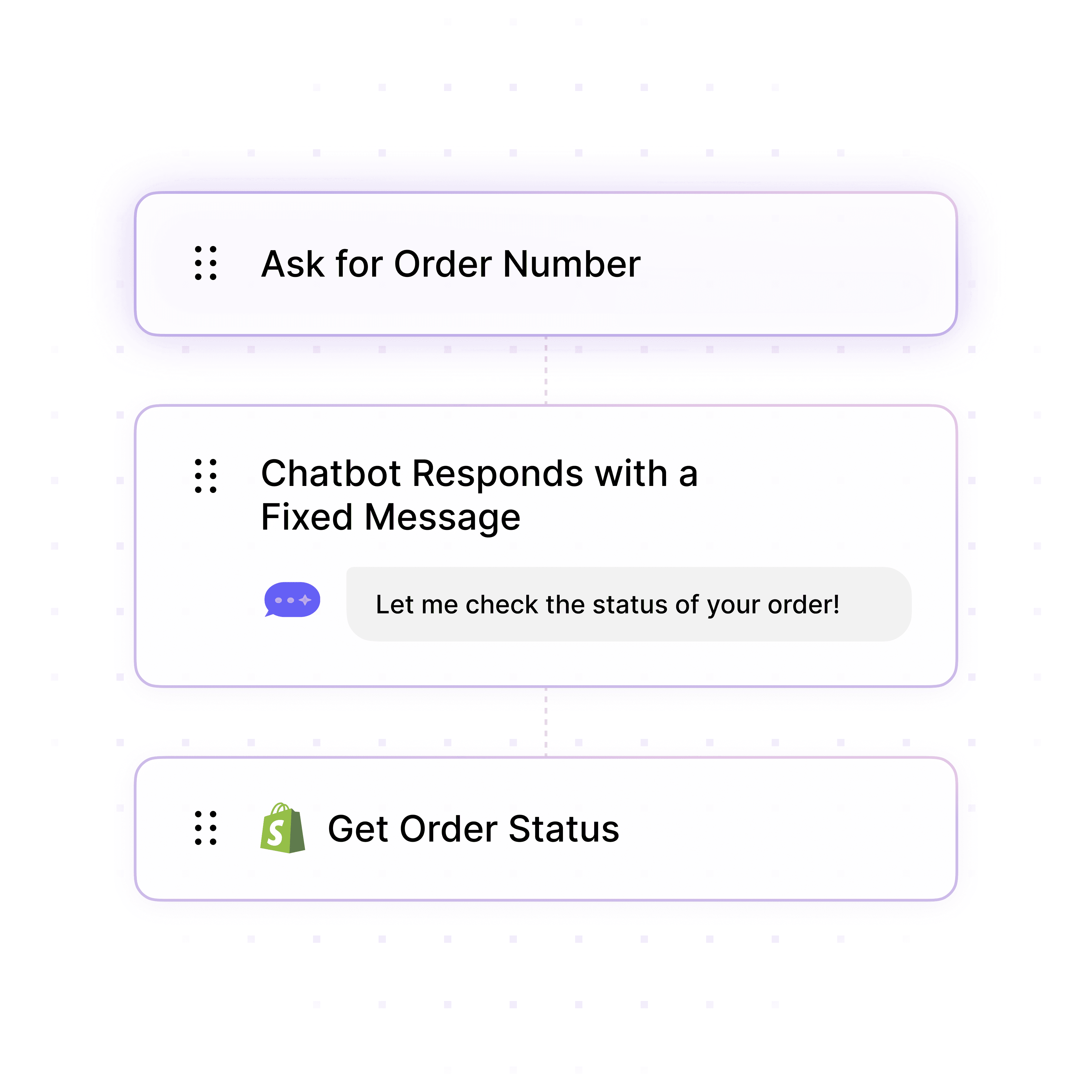

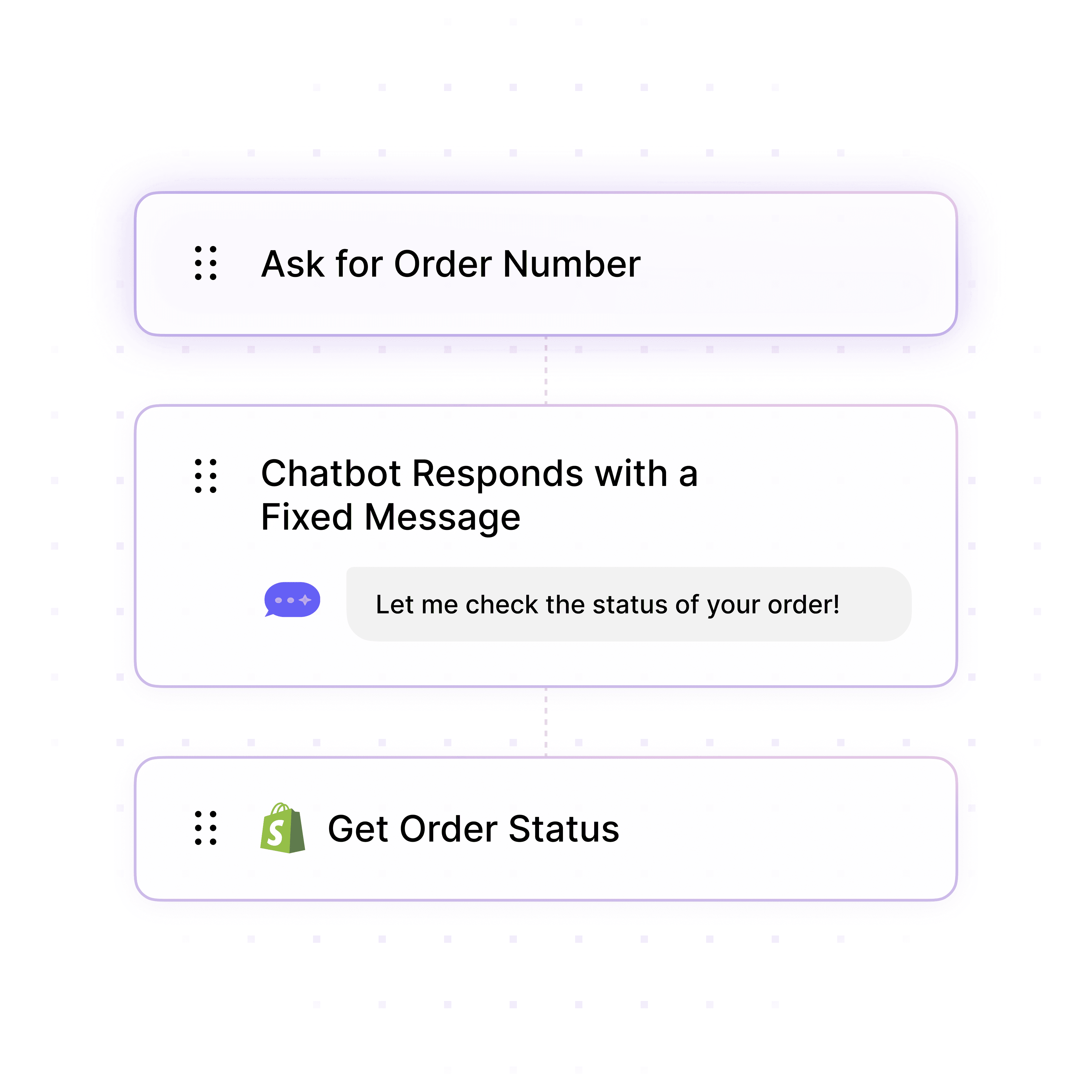

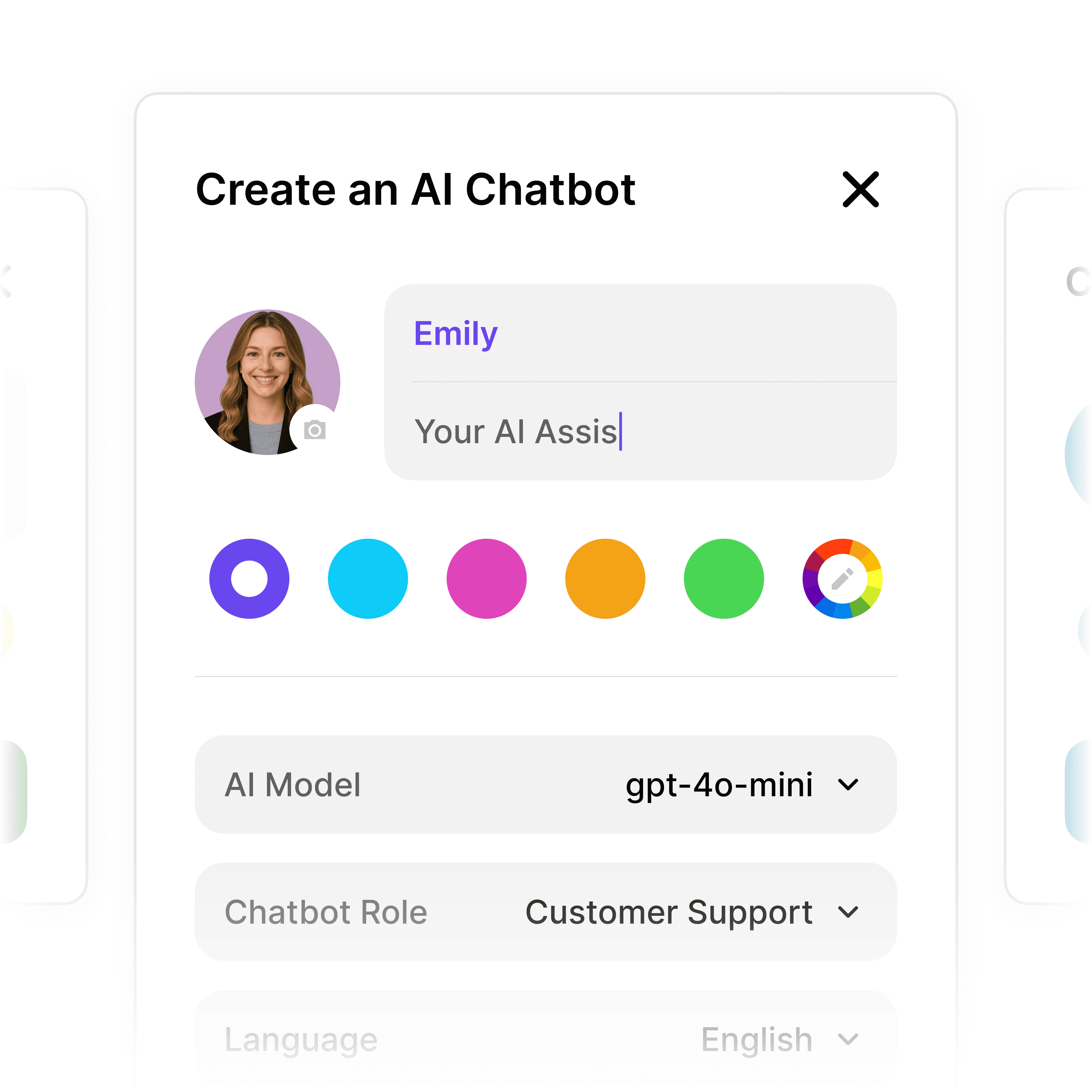

Deploy Your Manufacturing Knowledge Base Chatbot in Minutes

1

Create your AI chatbot – Pick the perfect AI model fit for your support needs.

2

Train AI with Docs, FAQs & Policies – Upload knowledge base files and site links.

3

Customise Workflows & Escalation Rules – AI handles what it can, and escalates what it can’t.

4

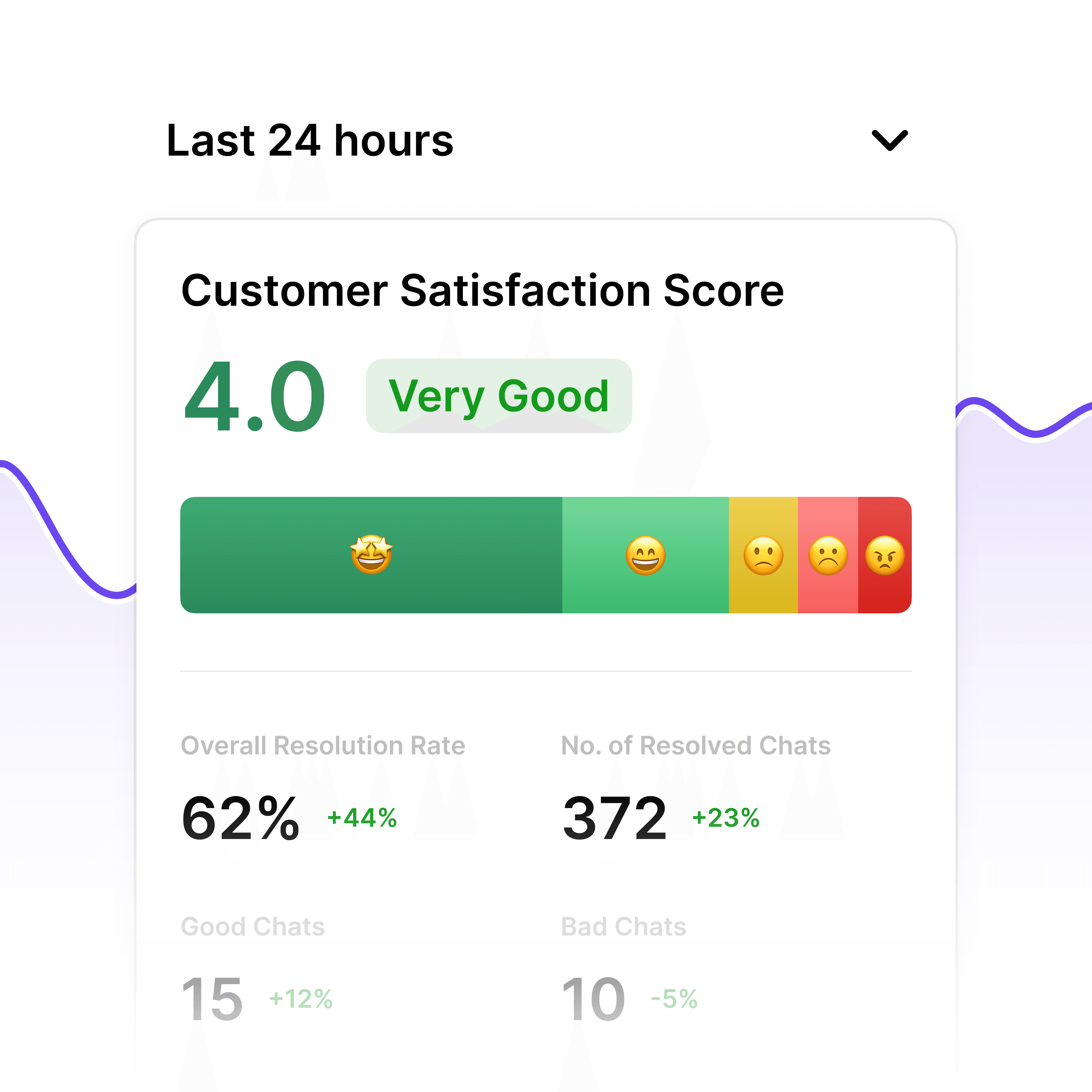

Monitor & Optimise with Analytics – See where customers get stuck and fine-tune responses.

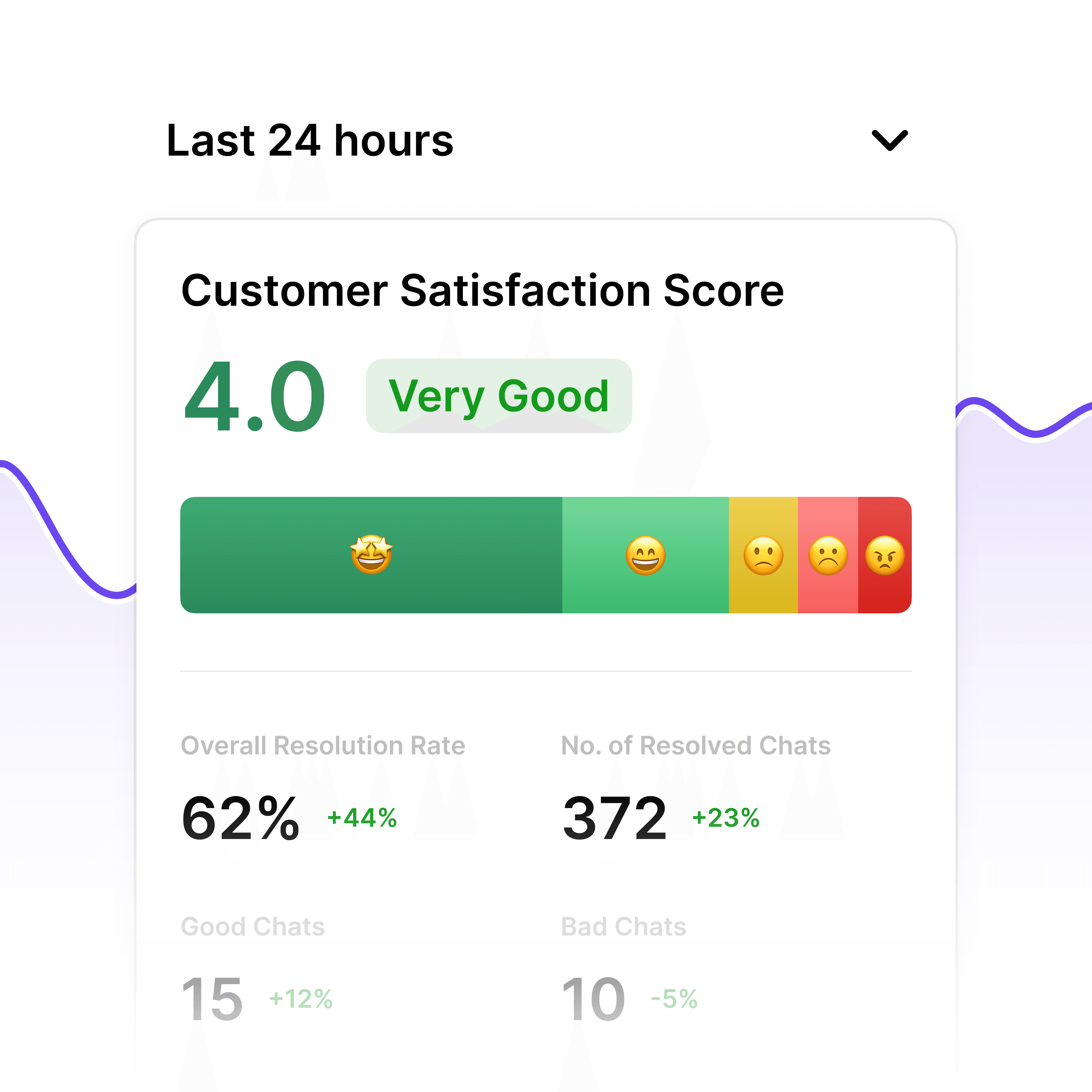

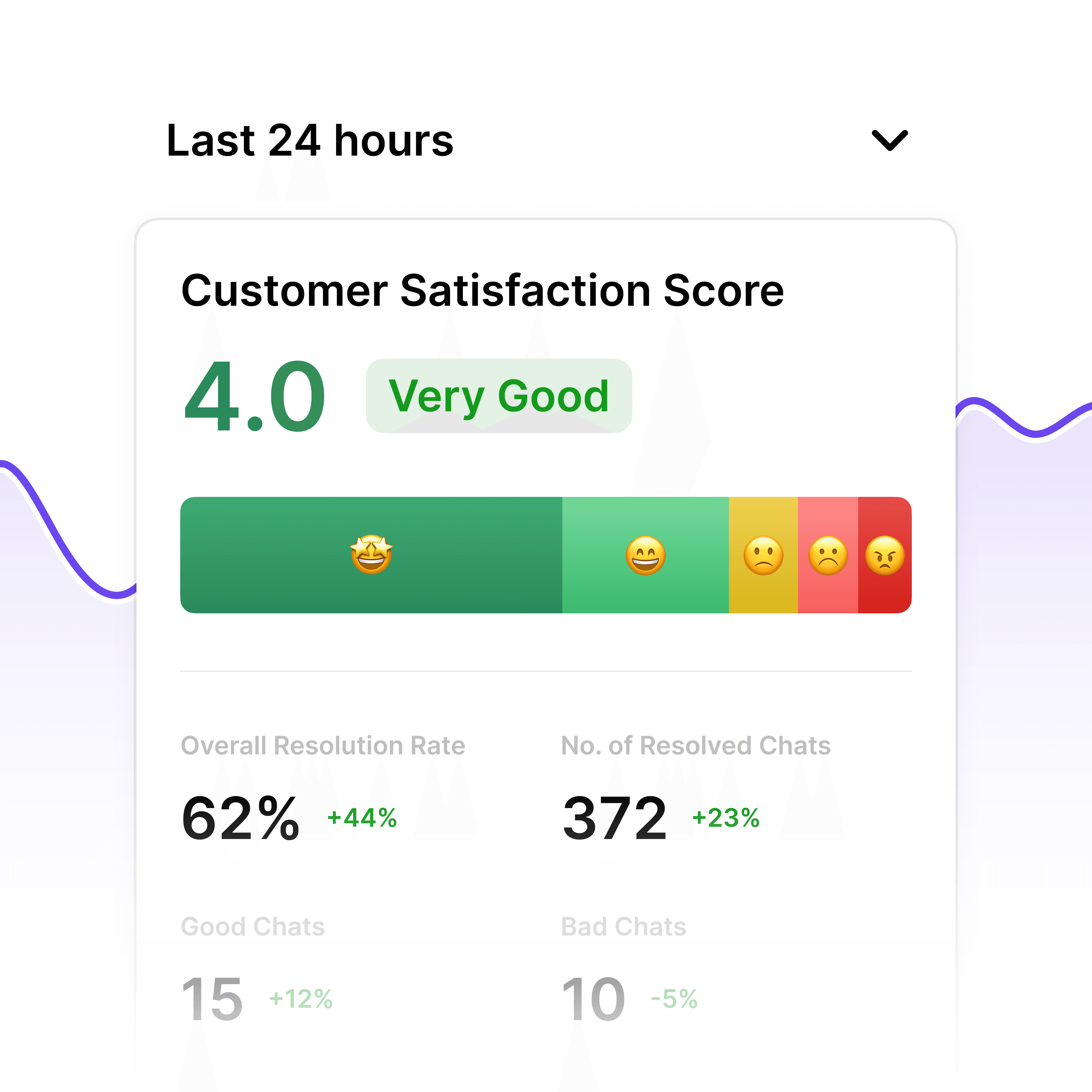

Operations Intelligence

Optimize Manufacturing Knowledge

Identify which equipment generates the most questions, common troubleshooting issues, frequently accessed procedures, and documentation gaps to improve training, maintenance planning, and process documentation.

Equipment patterns

Issue tracking

Documentation optimization

Operations Intelligence

Optimize Manufacturing Knowledge

Identify which equipment generates the most questions, common troubleshooting issues, frequently accessed procedures, and documentation gaps to improve training, maintenance planning, and process documentation.

Equipment patterns

Issue tracking

Documentation optimization

Operations Intelligence

Optimize Manufacturing Knowledge

Identify which equipment generates the most questions, common troubleshooting issues, frequently accessed procedures, and documentation gaps to improve training, maintenance planning, and process documentation.

Equipment patterns

Issue tracking

Documentation optimization

Multilingual Floor Support

Support Diverse Manufacturing Workforces

Provide knowledge base access in 100+ languages automatically, so operators and technicians can find procedures, specs, and safety information in their preferred language—critical for diverse manufacturing workforces.

100+ languages

Workforce diversity

Inclusive access

Multilingual Floor Support

Support Diverse Manufacturing Workforces

Provide knowledge base access in 100+ languages automatically, so operators and technicians can find procedures, specs, and safety information in their preferred language—critical for diverse manufacturing workforces.

100+ languages

Workforce diversity

Inclusive access

Multilingual Floor Support

Support Diverse Manufacturing Workforces

Provide knowledge base access in 100+ languages automatically, so operators and technicians can find procedures, specs, and safety information in their preferred language—critical for diverse manufacturing workforces.

100+ languages

Workforce diversity

Inclusive access

40+ Languages

Starts at $0.02/message

Available 24/7

Start Improving Floor Efficiency

14-day free trial. No credit card required

Testimonials

Businesses with successful customer service start

with Wonderchat

"Wonderchat has made it easier than ever to find the information I need without getting lost in the complexities. It also brings convenience and clarity to my searches."

Josh Levitsky

Global Head of Professional Services, Filewave

“Wonderchat has been a game-changer for bazuba. We’ve seen improved customer satisfaction and a noticeable boost in efficiency. Wonderchat handles our customer queries with precision and speed.

Julien Pflanzl

Web Development Lead, bazuba

“Ever since implementing Wonderchat on our site, I've seen up to a 70% reduction of customer support queries in my inbox.”

Bryce Conway

Founder and CEO, 10xTravel

"Wonderchat has given us the ability to offer real-time answers to our customer’s questions on their terms, pulling from our extensive portfolio of Insurance content. The response has been tremendous."

Ryan Hanley

Founder and President, Rogue Risk LLC

"Wonderchat has made it easier than ever to find the information I need without getting lost in the complexities. It also brings convenience and clarity to my searches."

Josh Levitsky

Global Head of Professional Services, Filewave

“Wonderchat has been a game-changer for bazuba. We’ve seen improved customer satisfaction and a noticeable boost in efficiency. Wonderchat handles our customer queries with precision and speed.

Julien Pflanzl

Web Development Lead, bazuba

“Ever since implementing Wonderchat on our site, I've seen up to a 70% reduction of customer support queries in my inbox.”

Bryce Conway

Founder and CEO, 10xTravel

"Wonderchat has given us the ability to offer real-time answers to our customer’s questions on their terms, pulling from our extensive portfolio of Insurance content. The response has been tremendous."

Ryan Hanley

Founder and President, Rogue Risk LLC

"Wonderchat has made it easier than ever to find the information I need without getting lost in the complexities. It also brings convenience and clarity to my searches."

Josh Levitsky

Global Head of Professional Services, Filewave

“Wonderchat has been a game-changer for bazuba. We’ve seen improved customer satisfaction and a noticeable boost in efficiency. Wonderchat handles our customer queries with precision and speed.

Julien Pflanzl

Web Development Lead, bazuba

“Ever since implementing Wonderchat on our site, I've seen up to a 70% reduction of customer support queries in my inbox.”

Bryce Conway

Founder and CEO, 10xTravel

"Wonderchat has given us the ability to offer real-time answers to our customer’s questions on their terms, pulling from our extensive portfolio of Insurance content. The response has been tremendous."

Ryan Hanley

Founder and President, Rogue Risk LLC

"Wonderchat has made it easier than ever to find the information I need without getting lost in the complexities. It also brings convenience and clarity to my searches."

Josh Levitsky

Global Head of Professional Services, Filewave

“Wonderchat has been a game-changer for bazuba. We’ve seen improved customer satisfaction and a noticeable boost in efficiency. Wonderchat handles our customer queries with precision and speed.

Julien Pflanzl

Web Development Lead, bazuba

“Ever since implementing Wonderchat on our site, I've seen up to a 70% reduction of customer support queries in my inbox.”

Bryce Conway

Founder and CEO, 10xTravel

"Wonderchat has given us the ability to offer real-time answers to our customer’s questions on their terms, pulling from our extensive portfolio of Insurance content. The response has been tremendous."

Ryan Hanley

Founder and President, Rogue Risk LLC

"Wonderchat has made it easier than ever to find the information I need without getting lost in the complexities. It also brings convenience and clarity to my searches."

Josh Levitsky

Global Head of Professional Services, Filewave

“Wonderchat has been a game-changer for bazuba. We’ve seen improved customer satisfaction and a noticeable boost in efficiency. Wonderchat handles our customer queries with precision and speed.

Julien Pflanzl

Web Development Lead, bazuba

“Ever since implementing Wonderchat on our site, I've seen up to a 70% reduction of customer support queries in my inbox.”

Bryce Conway

Founder and CEO, 10xTravel

"Wonderchat has given us the ability to offer real-time answers to our customer’s questions on their terms, pulling from our extensive portfolio of Insurance content. The response has been tremendous."

Ryan Hanley

Founder and President, Rogue Risk LLC

"Wonderchat has made it easier than ever to find the information I need without getting lost in the complexities. It also brings convenience and clarity to my searches."

Josh Levitsky

Global Head of Professional Services, Filewave

“Wonderchat has been a game-changer for bazuba. We’ve seen improved customer satisfaction and a noticeable boost in efficiency. Wonderchat handles our customer queries with precision and speed.

Julien Pflanzl

Web Development Lead, bazuba

“Ever since implementing Wonderchat on our site, I've seen up to a 70% reduction of customer support queries in my inbox.”

Bryce Conway

Founder and CEO, 10xTravel

"Wonderchat has given us the ability to offer real-time answers to our customer’s questions on their terms, pulling from our extensive portfolio of Insurance content. The response has been tremendous."

Ryan Hanley

Founder and President, Rogue Risk LLC

"Wonderchat has made it easier than ever to find the information I need without getting lost in the complexities. It also brings convenience and clarity to my searches."

Josh Levitsky

Global Head of Professional Services, Filewave

“Wonderchat has been a game-changer for bazuba. We’ve seen improved customer satisfaction and a noticeable boost in efficiency. Wonderchat handles our customer queries with precision and speed.

Julien Pflanzl

Web Development Lead, bazuba

“Ever since implementing Wonderchat on our site, I've seen up to a 70% reduction of customer support queries in my inbox.”

Bryce Conway

Founder and CEO, 10xTravel

"Wonderchat has given us the ability to offer real-time answers to our customer’s questions on their terms, pulling from our extensive portfolio of Insurance content. The response has been tremendous."

Ryan Hanley

Founder and President, Rogue Risk LLC

"Wonderchat has made it easier than ever to find the information I need without getting lost in the complexities. It also brings convenience and clarity to my searches."

Josh Levitsky

Global Head of Professional Services, Filewave

“Wonderchat has been a game-changer for bazuba. We’ve seen improved customer satisfaction and a noticeable boost in efficiency. Wonderchat handles our customer queries with precision and speed.

Julien Pflanzl

Web Development Lead, bazuba

“Ever since implementing Wonderchat on our site, I've seen up to a 70% reduction of customer support queries in my inbox.”

Bryce Conway

Founder and CEO, 10xTravel

"Wonderchat has given us the ability to offer real-time answers to our customer’s questions on their terms, pulling from our extensive portfolio of Insurance content. The response has been tremendous."

Ryan Hanley

Founder and President, Rogue Risk LLC

"Wonderchat has made it easier than ever to find the information I need without getting lost in the complexities. It also brings convenience and clarity to my searches."

Josh Levitsky

Global Head of Professional Services, Filewave

“Wonderchat has been a game-changer for bazuba. We’ve seen improved customer satisfaction and a noticeable boost in efficiency. Wonderchat handles our customer queries with precision and speed.

Julien Pflanzl

Web Development Lead, bazuba

“Ever since implementing Wonderchat on our site, I've seen up to a 70% reduction of customer support queries in my inbox.”

Bryce Conway

Founder and CEO, 10xTravel

"Wonderchat has given us the ability to offer real-time answers to our customer’s questions on their terms, pulling from our extensive portfolio of Insurance content. The response has been tremendous."

Ryan Hanley

Founder and President, Rogue Risk LLC

"Wonderchat has made it easier than ever to find the information I need without getting lost in the complexities. It also brings convenience and clarity to my searches."

Josh Levitsky

Global Head of Professional Services, Filewave

“Wonderchat has been a game-changer for bazuba. We’ve seen improved customer satisfaction and a noticeable boost in efficiency. Wonderchat handles our customer queries with precision and speed.

Julien Pflanzl

Web Development Lead, bazuba

“Ever since implementing Wonderchat on our site, I've seen up to a 70% reduction of customer support queries in my inbox.”

Bryce Conway

Founder and CEO, 10xTravel

"Wonderchat has given us the ability to offer real-time answers to our customer’s questions on their terms, pulling from our extensive portfolio of Insurance content. The response has been tremendous."

Ryan Hanley

Founder and President, Rogue Risk LLC

"Wonderchat has made it easier than ever to find the information I need without getting lost in the complexities. It also brings convenience and clarity to my searches."

Josh Levitsky

Global Head of Professional Services, Filewave

“Wonderchat has been a game-changer for bazuba. We’ve seen improved customer satisfaction and a noticeable boost in efficiency. Wonderchat handles our customer queries with precision and speed.

Julien Pflanzl

Web Development Lead, bazuba

“Ever since implementing Wonderchat on our site, I've seen up to a 70% reduction of customer support queries in my inbox.”

Bryce Conway

Founder and CEO, 10xTravel

"Wonderchat has given us the ability to offer real-time answers to our customer’s questions on their terms, pulling from our extensive portfolio of Insurance content. The response has been tremendous."

Ryan Hanley

Founder and President, Rogue Risk LLC

"Wonderchat has made it easier than ever to find the information I need without getting lost in the complexities. It also brings convenience and clarity to my searches."

Josh Levitsky

Global Head of Professional Services, Filewave

“Wonderchat has been a game-changer for bazuba. We’ve seen improved customer satisfaction and a noticeable boost in efficiency. Wonderchat handles our customer queries with precision and speed.

Julien Pflanzl

Web Development Lead, bazuba

“Ever since implementing Wonderchat on our site, I've seen up to a 70% reduction of customer support queries in my inbox.”

Bryce Conway

Founder and CEO, 10xTravel

"Wonderchat has given us the ability to offer real-time answers to our customer’s questions on their terms, pulling from our extensive portfolio of Insurance content. The response has been tremendous."

Ryan Hanley

Founder and President, Rogue Risk LLC

"Wonderchat has made it easier than ever to find the information I need without getting lost in the complexities. It also brings convenience and clarity to my searches."

Josh Levitsky

Global Head of Professional Services, Filewave

“Wonderchat has been a game-changer for bazuba. We’ve seen improved customer satisfaction and a noticeable boost in efficiency. Wonderchat handles our customer queries with precision and speed.

Julien Pflanzl

Web Development Lead, bazuba

“Ever since implementing Wonderchat on our site, I've seen up to a 70% reduction of customer support queries in my inbox.”

Bryce Conway

Founder and CEO, 10xTravel

"Wonderchat has given us the ability to offer real-time answers to our customer’s questions on their terms, pulling from our extensive portfolio of Insurance content. The response has been tremendous."

Ryan Hanley

Founder and President, Rogue Risk LLC

"Wonderchat has made it easier than ever to find the information I need without getting lost in the complexities. It also brings convenience and clarity to my searches."

Josh Levitsky

Global Head of Professional Services, Filewave

“Wonderchat has been a game-changer for bazuba. We’ve seen improved customer satisfaction and a noticeable boost in efficiency. Wonderchat handles our customer queries with precision and speed.

Julien Pflanzl

Web Development Lead, bazuba

“Ever since implementing Wonderchat on our site, I've seen up to a 70% reduction of customer support queries in my inbox.”

Bryce Conway

Founder and CEO, 10xTravel

"Wonderchat has given us the ability to offer real-time answers to our customer’s questions on their terms, pulling from our extensive portfolio of Insurance content. The response has been tremendous."

Ryan Hanley

Founder and President, Rogue Risk LLC

"Wonderchat has made it easier than ever to find the information I need without getting lost in the complexities. It also brings convenience and clarity to my searches."

Josh Levitsky

Global Head of Professional Services, Filewave

“Wonderchat has been a game-changer for bazuba. We’ve seen improved customer satisfaction and a noticeable boost in efficiency. Wonderchat handles our customer queries with precision and speed.

Julien Pflanzl

Web Development Lead, bazuba

“Ever since implementing Wonderchat on our site, I've seen up to a 70% reduction of customer support queries in my inbox.”

Bryce Conway

Founder and CEO, 10xTravel

"Wonderchat has given us the ability to offer real-time answers to our customer’s questions on their terms, pulling from our extensive portfolio of Insurance content. The response has been tremendous."

Ryan Hanley

Founder and President, Rogue Risk LLC

"Wonderchat has made it easier than ever to find the information I need without getting lost in the complexities. It also brings convenience and clarity to my searches."

Josh Levitsky

Global Head of Professional Services, Filewave

“Wonderchat has been a game-changer for bazuba. We’ve seen improved customer satisfaction and a noticeable boost in efficiency. Wonderchat handles our customer queries with precision and speed.

Julien Pflanzl

Web Development Lead, bazuba

“Ever since implementing Wonderchat on our site, I've seen up to a 70% reduction of customer support queries in my inbox.”

Bryce Conway

Founder and CEO, 10xTravel

"Wonderchat has given us the ability to offer real-time answers to our customer’s questions on their terms, pulling from our extensive portfolio of Insurance content. The response has been tremendous."

Ryan Hanley

Founder and President, Rogue Risk LLC

Industry Grade Compliance

Wonderchat is GDPR compliant and AICPA SOC 2 Certified.

FAQ

What types of manufacturing knowledge can the chatbot provide?

The chatbot provides instant access to production SOPs, equipment operation manuals, maintenance procedures, safety protocols, quality specifications, troubleshooting guides, torque specs, assembly instructions, error code resolutions, and process documentation—essentially any manufacturing floor knowledge you upload.

Can floor workers access it on mobile devices?

Yes! Manufacturing teams can access the chatbot via mobile phones, tablets, or floor kiosks. This lets operators, technicians, and supervisors look up procedures, specs, and troubleshooting guidance right at their workstation or equipment without leaving the floor or searching through binders.

How does it reduce production downtime?

When equipment errors occur, operators get instant troubleshooting guidance and error code resolutions instead of waiting for maintenance or engineering support. When spec questions arise, operators find torque values, tolerances, or assembly instructions immediately rather than halting production to search through manuals—minimizing downtime.

Does it work for multilingual manufacturing workforces?

Yes! Wonderchat supports 100+ languages and automatically responds in the operator's preferred language, even if your SOPs and manuals are in English. This ensures diverse manufacturing workforces can access critical procedures, safety information, and troubleshooting guidance in their native language.

How do we keep it updated when SOPs or specs change?

Wonderchat offers automatic data syncing—weekly on Turbo plans, daily on Enterprise. When production SOPs, quality specs, or equipment procedures are updated, the AI retrains automatically to reflect current documentation, ensuring operators always access the latest approved procedures.

Can it help with new operator training and onboarding?

Absolutely! New manufacturing operators can use the chatbot to quickly find procedures, learn equipment operation, understand safety protocols, and access specs during their ramp-up period—accelerating training and reducing the burden on experienced operators and trainers.

FAQ

What types of manufacturing knowledge can the chatbot provide?

The chatbot provides instant access to production SOPs, equipment operation manuals, maintenance procedures, safety protocols, quality specifications, troubleshooting guides, torque specs, assembly instructions, error code resolutions, and process documentation—essentially any manufacturing floor knowledge you upload.

Can floor workers access it on mobile devices?

Yes! Manufacturing teams can access the chatbot via mobile phones, tablets, or floor kiosks. This lets operators, technicians, and supervisors look up procedures, specs, and troubleshooting guidance right at their workstation or equipment without leaving the floor or searching through binders.

How does it reduce production downtime?

When equipment errors occur, operators get instant troubleshooting guidance and error code resolutions instead of waiting for maintenance or engineering support. When spec questions arise, operators find torque values, tolerances, or assembly instructions immediately rather than halting production to search through manuals—minimizing downtime.

Does it work for multilingual manufacturing workforces?

Yes! Wonderchat supports 100+ languages and automatically responds in the operator's preferred language, even if your SOPs and manuals are in English. This ensures diverse manufacturing workforces can access critical procedures, safety information, and troubleshooting guidance in their native language.

How do we keep it updated when SOPs or specs change?

Wonderchat offers automatic data syncing—weekly on Turbo plans, daily on Enterprise. When production SOPs, quality specs, or equipment procedures are updated, the AI retrains automatically to reflect current documentation, ensuring operators always access the latest approved procedures.

Can it help with new operator training and onboarding?

Absolutely! New manufacturing operators can use the chatbot to quickly find procedures, learn equipment operation, understand safety protocols, and access specs during their ramp-up period—accelerating training and reducing the burden on experienced operators and trainers.

FAQ

What types of manufacturing knowledge can the chatbot provide?

The chatbot provides instant access to production SOPs, equipment operation manuals, maintenance procedures, safety protocols, quality specifications, troubleshooting guides, torque specs, assembly instructions, error code resolutions, and process documentation—essentially any manufacturing floor knowledge you upload.

Can floor workers access it on mobile devices?

Yes! Manufacturing teams can access the chatbot via mobile phones, tablets, or floor kiosks. This lets operators, technicians, and supervisors look up procedures, specs, and troubleshooting guidance right at their workstation or equipment without leaving the floor or searching through binders.

How does it reduce production downtime?

When equipment errors occur, operators get instant troubleshooting guidance and error code resolutions instead of waiting for maintenance or engineering support. When spec questions arise, operators find torque values, tolerances, or assembly instructions immediately rather than halting production to search through manuals—minimizing downtime.

Does it work for multilingual manufacturing workforces?

Yes! Wonderchat supports 100+ languages and automatically responds in the operator's preferred language, even if your SOPs and manuals are in English. This ensures diverse manufacturing workforces can access critical procedures, safety information, and troubleshooting guidance in their native language.

How do we keep it updated when SOPs or specs change?

Wonderchat offers automatic data syncing—weekly on Turbo plans, daily on Enterprise. When production SOPs, quality specs, or equipment procedures are updated, the AI retrains automatically to reflect current documentation, ensuring operators always access the latest approved procedures.

Can it help with new operator training and onboarding?

Absolutely! New manufacturing operators can use the chatbot to quickly find procedures, learn equipment operation, understand safety protocols, and access specs during their ramp-up period—accelerating training and reducing the burden on experienced operators and trainers.

40+ Languages

Starts at $0.02/message

Available 24/7

Start Improving Floor Efficiency

14-day free trial. No credit card required

The platform to build AI agents that feel human

Site

© 2025 Wonderchat Private Limited

The platform to build AI agents that feel human

Site

© 2025 Wonderchat Private Limited

The platform to build AI agents that feel human

Site

© 2025 Wonderchat Private Limited